Molding Forging Casting . metal shaping techniques forging and casting, explaining their processes, advantages, and ideal. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. So, casting process provides greater. Learn about their unique benefits, applications, and which method is best for your manufacturing needs. pros and cons of technical advantages of forging. the forging and casting processes involve shaping metal through compressive forces and molding molten. One of the main advantages of forging is the strength it. discover the key differences between casting and forging, two essential metal forming processes.

from mungfali.com

the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. pros and cons of technical advantages of forging. metal shaping techniques forging and casting, explaining their processes, advantages, and ideal. Learn about their unique benefits, applications, and which method is best for your manufacturing needs. discover the key differences between casting and forging, two essential metal forming processes. One of the main advantages of forging is the strength it. So, casting process provides greater. the forging and casting processes involve shaping metal through compressive forces and molding molten.

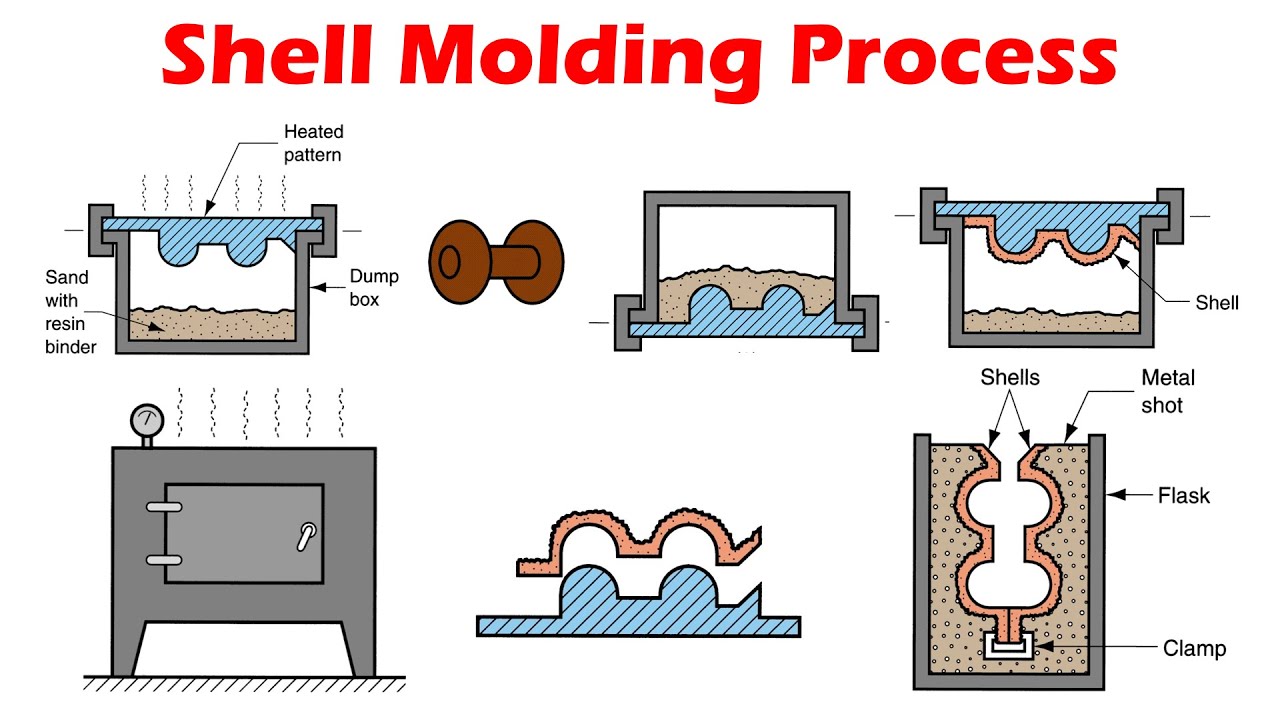

Shell Molding Casting Process

Molding Forging Casting So, casting process provides greater. pros and cons of technical advantages of forging. So, casting process provides greater. discover the key differences between casting and forging, two essential metal forming processes. metal shaping techniques forging and casting, explaining their processes, advantages, and ideal. One of the main advantages of forging is the strength it. Learn about their unique benefits, applications, and which method is best for your manufacturing needs. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. the forging and casting processes involve shaping metal through compressive forces and molding molten.

From www.tfgusa.com

Custom Centrifugal Casting Manufacturing Company TFG USA Molding Forging Casting the forging and casting processes involve shaping metal through compressive forces and molding molten. Learn about their unique benefits, applications, and which method is best for your manufacturing needs. discover the key differences between casting and forging, two essential metal forming processes. metal shaping techniques forging and casting, explaining their processes, advantages, and ideal. One of the. Molding Forging Casting.

From www.studypool.com

SOLUTION Manufacturing process complete ppt intro machining forming Molding Forging Casting the forging and casting processes involve shaping metal through compressive forces and molding molten. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. Learn about their unique benefits, applications, and which method is best for your manufacturing needs. One of the main advantages. Molding Forging Casting.

From mungfali.com

Shell Molding Casting Process Molding Forging Casting One of the main advantages of forging is the strength it. discover the key differences between casting and forging, two essential metal forming processes. the forging and casting processes involve shaping metal through compressive forces and molding molten. pros and cons of technical advantages of forging. metal shaping techniques forging and casting, explaining their processes, advantages,. Molding Forging Casting.

From castingforgingmolding.com

Casting Molding Molding Forging Casting the forging and casting processes involve shaping metal through compressive forces and molding molten. pros and cons of technical advantages of forging. discover the key differences between casting and forging, two essential metal forming processes. metal shaping techniques forging and casting, explaining their processes, advantages, and ideal. Learn about their unique benefits, applications, and which method. Molding Forging Casting.

From tacitceiyrs.blogspot.com

Sand Casting Process tacitceiyrs Molding Forging Casting So, casting process provides greater. pros and cons of technical advantages of forging. One of the main advantages of forging is the strength it. discover the key differences between casting and forging, two essential metal forming processes. the forging and casting processes involve shaping metal through compressive forces and molding molten. the process of casting involves. Molding Forging Casting.

From www.innovativetoolanddesign.com

Castings, and Rubber Molding Innovative Molding Forging Casting Learn about their unique benefits, applications, and which method is best for your manufacturing needs. the forging and casting processes involve shaping metal through compressive forces and molding molten. discover the key differences between casting and forging, two essential metal forming processes. metal shaping techniques forging and casting, explaining their processes, advantages, and ideal. pros and. Molding Forging Casting.

From monroeengineering.com

The 6Step Process of Sand Casting Molding OneMonroe Molding Forging Casting pros and cons of technical advantages of forging. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. One of the main advantages of forging is the strength it. discover the key differences between casting and forging, two essential metal forming processes. Learn. Molding Forging Casting.

From www.various.co.in

Mould For Casting Process Precision Machining Works in CNC VMC HMC Molding Forging Casting pros and cons of technical advantages of forging. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. One of the main advantages of forging is the strength it. the forging and casting processes involve shaping metal through compressive forces and molding molten.. Molding Forging Casting.

From www.mfiglobal.com

Contract Metal Manufacturing Castings Stampings Molding Forging Casting discover the key differences between casting and forging, two essential metal forming processes. Learn about their unique benefits, applications, and which method is best for your manufacturing needs. the forging and casting processes involve shaping metal through compressive forces and molding molten. So, casting process provides greater. the process of casting involves pouring molten metal into a. Molding Forging Casting.

From paiwoshaft.en.made-in-china.com

Cold Iron Difference Between Casting and Moulding Inconel Molding Forging Casting Learn about their unique benefits, applications, and which method is best for your manufacturing needs. discover the key differences between casting and forging, two essential metal forming processes. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. So, casting process provides greater. One. Molding Forging Casting.

From www.iqsdirectory.com

Open vs. Closed Die Process, Differences & Benefits Molding Forging Casting pros and cons of technical advantages of forging. discover the key differences between casting and forging, two essential metal forming processes. One of the main advantages of forging is the strength it. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. So,. Molding Forging Casting.

From www.tfgusa.com

Metal Processes, Methods, and Applications TFGUSA Molding Forging Casting metal shaping techniques forging and casting, explaining their processes, advantages, and ideal. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. discover the key differences between casting and forging, two essential metal forming processes. Learn about their unique benefits, applications, and which. Molding Forging Casting.

From prototechasia.com

What is Plastic Injection Molding? Our Comprehensive Overview Molding Forging Casting discover the key differences between casting and forging, two essential metal forming processes. One of the main advantages of forging is the strength it. So, casting process provides greater. metal shaping techniques forging and casting, explaining their processes, advantages, and ideal. the forging and casting processes involve shaping metal through compressive forces and molding molten. Learn about. Molding Forging Casting.

From www.castingforgingpart.com

China Iron Castings, Steel Castings, Manufacturers, Suppliers Molding Forging Casting One of the main advantages of forging is the strength it. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. Learn about their unique benefits, applications, and which method is best for your manufacturing needs. pros and cons of technical advantages of forging.. Molding Forging Casting.

From www.weld2cast.com

Sand Casting Weld2Cast Molding Forging Casting the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. One of the main advantages of forging is the strength it. Learn about their unique benefits, applications, and which method is best for your manufacturing needs. So, casting process provides greater. discover the key. Molding Forging Casting.

From www.weld2cast.com

Shell Moulding Casting Weld2Cast Molding Forging Casting metal shaping techniques forging and casting, explaining their processes, advantages, and ideal. So, casting process provides greater. pros and cons of technical advantages of forging. the forging and casting processes involve shaping metal through compressive forces and molding molten. One of the main advantages of forging is the strength it. the process of casting involves pouring. Molding Forging Casting.

From www.youtube.com

Sand Casting Molding Processes Binders Patterns Core Making Molding Forging Casting One of the main advantages of forging is the strength it. discover the key differences between casting and forging, two essential metal forming processes. So, casting process provides greater. the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. metal shaping techniques forging. Molding Forging Casting.

From www.castingforgingpart.com

China Iron Castings, Steel Castings, Manufacturers, Suppliers Molding Forging Casting the process of casting involves pouring molten metal into a mould and then letting it cool and harden before removing it from the mould. the forging and casting processes involve shaping metal through compressive forces and molding molten. Learn about their unique benefits, applications, and which method is best for your manufacturing needs. discover the key differences. Molding Forging Casting.